Vapour Corrosion Inhibitors Film

VCI FILM MAKES EXTENSIVE USE OF SPECIALISED INHIBITORS.

These Inhibitors take the form of both Vapour Corrosion Inhibitors Vapour Corrosion Inhibitor (VCI) and Contact Corrosion Inhibitors (CCI). These specialised and tailored additives become an integral part of the final products Industrial Shrink Wrap Solutions offers our clients.

Industrial Shrink Wrap Solutions selection of films offer excellent physical protection from water and moisture. Each material is tailored for a specific application.

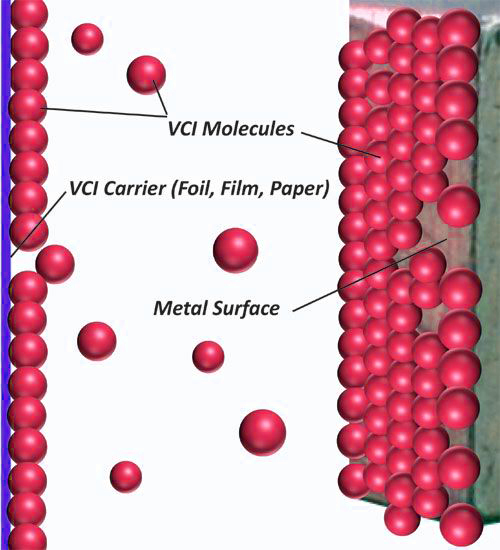

Our VCI’s provide long term protection from corrosion through direct contact and also via a corrosion preventing vapour (VCI) released directly from our product. At a molecular level our VCI inhibitors suppress corrosion in three ways;

- The VCI passivate the electron flow between anode & cathode areas on the metal surface.

- The VCI forms a physical hydrophobic layer that prevents water & moisture directly contacting the metal & acting as an electrolyte.

- The VCI regulates the PH value of the electrolyte.

Put very simply the corrosion inhibitors in Industrial Shrink Wrap Solutions product range are drawn to metal surfaces, the attraction is so strong that a vapour of inhibitors will build a VCI skin over your product. This 3-5 micron thick barrier prevents oxidisation – stopping corrosion. Remove the packaging containing VCI’s and this barrier will begin to dissipate – leaving your componentry corrosion free and ready to use.

VOLATILITY

The most notable feature of the Industrial Shrink Wrap Solutions is their volatility. The Vapour Corrosion Inhibitor (VCI) inhibitors do not need to touch your componentry to do their job. Industrial Shrink Wrap Solutions corrosion preventative additive migrate to where they are needed. This allows the hidden recesses and most complex of shapes to benefit from a continuous, unbroken molecular barrier.

- Vaporise.

- Are attracted to the metal surface.

- Passivate the metal surface.

- Create a barrier.

- Prevent oxidation.

- Keeps working.

HOW DO WE DO IT?

Industrial Shrink Wrap Solutions offers a large range of VCI packaging materials each tailored to meet the different demands for protection from corrosion. The expert team at Industrial Shrink Wrap Solutions will help you determine the best combination of materials and packaging techniques to meets your specific requirements.

The following guidelines are recommended:

- Ensure the parts to be stored are clean & dry

All parts to be packed must be clean & dry. Gloves must be worn when handling parts to avoid leaving acidic, corrosion causing finger prints.

DO NOT pack hot parts. Where possible, the ambient temperature & the temperature of the part should be the same to prevent condensation from forming inside the pack. - Apply a barrier

An often overlooked key to preventing corrosion is to control the environment in which your product will be stored. Industrial Shrink Wrap Solutions has developed a range of high barrier property films and foils that will provide a controlled environment. Industrial Shrink Wrap Solutions can provide solutions that meet the same exacting specification and standards required by the defence or fine art sectors. Australian Inhibitors films and foils are impregnated with VCI technologies ensuring the corrosion prevention we are known for is an integral part of our barrier materials. - Humidity control

The length of your storage period and the environmental conditions during the storage period will determine the desiccants solution that is offered. Desiccants reduce humidity to below critical levels and work to maintain this level. Controlling ambient conditions in this manner prolongs the storage life of your componentry. - Case

Possibly the most important barriers between your product and the outside world is the case it will be shipped or stored in. A well-designed shipping case is the key to safe transportation. The team at Industrial Shrink wrap Solutions understand this and have the capability to develop & provide the ideal solution in conjunction with Cases and Crates. Our longstanding relationship with this company that specialise in Industrial Packaging ensures the finest details are not overlooked.